DEHYDRATION

industrial-duty,

state-of-the-art

rotary dryers

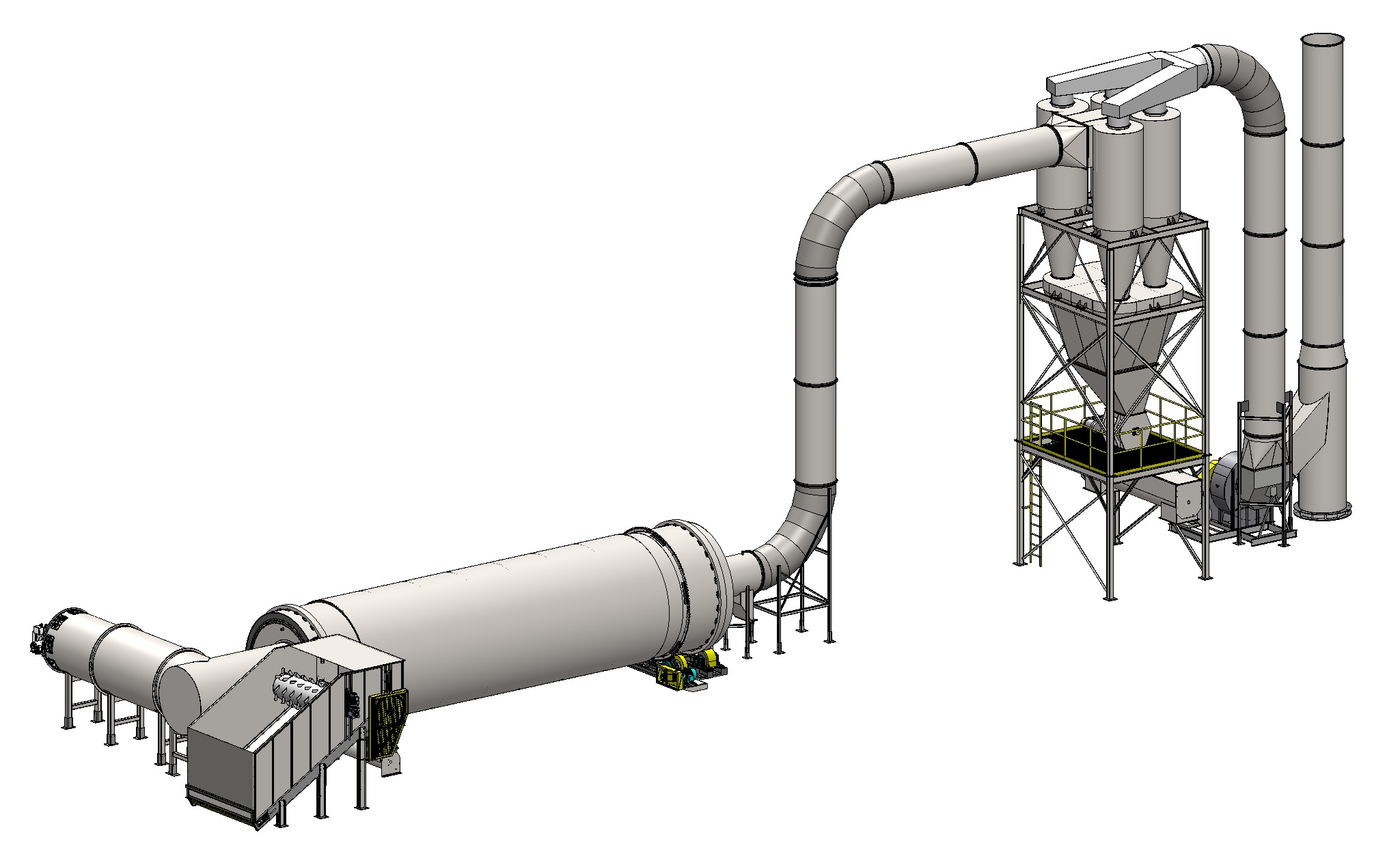

Omega’s Rotary Dryers are able to process a wide variety of feedstocks efficiently and economically.

Our proprietary reverse-flow design prevents product build up and volatilization, as well as mitigates the risk of fires and explosion. The robust construction consists of fully welded, tailored flight geometry and arrangement which helps to ensure efficient heat transfer.

The forged steel drum tracks offer an adjustable wedge assembly and have no internal moving parts, and the saddle chain drive assembly offers a low-maintenance operation.

Additional Features:

Drums are equipped with service access

Can be located within or with no building

Engineered and designed for new projects as well as drop-in replacements

Utilize multiple sources of thermal energy including waste thermal energy streams

Feedstock moisture can range from 10% - 90% (wet basis) and vary in densities

Rotary Dryers range from 6 to 14 feet diameter and up to 70 feet long

Evaporation rate ranging from 3,000 pph to 30,000 pph per line

Our Rotary Dryers Process various feedstocks such as:

Lignocellulose

Forages

Grains

Organic and Food Waste

Municipal Solid Waste

Paper sludge

Sewage sludge, etc.

MSW

Animal by products

Biosolids

Minerals

Rotary Dryer system

Multi-Pass rotary dryer Technology